When I was young, I couldn’t afford Air Jordans™. Of course, Nike® had struck absolute gold with their Air Jordan basketball sneakers. Using Michael Jordan’s name and trademark airborne likeness, Nike got the greatest player in the NBA to endorse their premiere shoe, and the rest is athletic wear history. Other companies produced great shoes to be sure; I had a pair of Converse, which were great. Adidas made shoes that rap superstars Run-DMC made famous. And since then, countless basketball superstars have endorsed their own footwear designs for dozens of companies, but none have yet to surpass Nike’s Air Jordan as the gold standard for basketball sneakers.

Unfortunately, I couldn’t afford Air Jordans. So, while my high school basketball teammates were squeaking through practice confidently in their Jordans, I was working my less-than-premium body through half-court drills in my less-than-premium shoes. They paid a little more for their Nikes, but the quality they received, and perhaps just as importantly, the confidence they acquired from investing in the top shoe on the market, made them perform that much better, and their Jordans, which they cared for meticulously, far outlasted mine, making their initial investment all the more worthwhile.

This is what Marshalltown trowels are to archaeology; they are the Nike Air Jordans of archaeology, and I learned this the hard way.

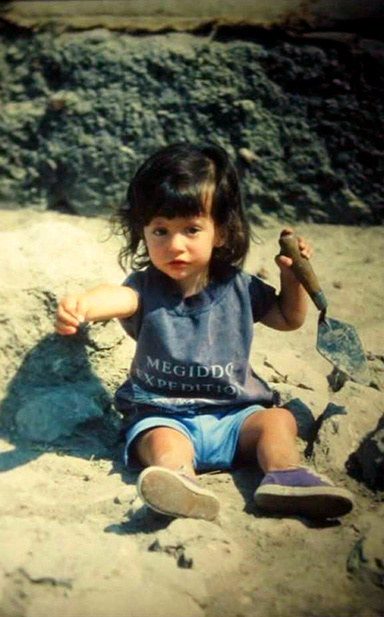

When I learned that I would be traveling to Israel to participate in my first archaeological excavation at Banias (ancient Caesarea Philippi) as part of my MDiv curriculum at Pepperdine University, I was given a standard list of items that I needed to procure before we departed. Anyone who has been on an archaeological excavation has seen a similar list of items: long pants, multiple shirts (that you don’t mind throwing away or burning when the dig is over), sturdy boots, sunscreen, a wide-brimmed hat, water bottle, and many other items for bathing and sleeping. But the one piece of digging equipment we are asked to buy was a trowel. Large pieces of equipment like pickaxes, hoes, and buckets are provided by the excavation, but the hand trowel is the small piece of equipment that you never want to share. Like an angler’s favorite fishing pole or a police officer’s sidearm, a trowel is cared for and customized just for an archaeologist’s hand. You don’t want it to get bent or worn, or worse yet—taken by another volunteer in the early morning distribution of tools.

I needed a trowel, so I went down to my local Ace Hardware and bought a pointed, 5-inch masonry trowel and a gardening scoop and was ready for my first excavation.

I arrived in Israel—a complete novice—decked out in my convertible zip-leg trousers and tie-dye t-shirts that my sister had made for me (the latter of which would become a trademark of mine on dig sites). I went to my assigned square and met my seasoned square supervisor, who trained us in the essentials: how to pick, hoe, shovel, and how to trim a baulk. Trimming a baulk, now called a “cut” on many excavations, is perhaps one of the most important activities on an excavation, as it allows you see changes in the soil as you descend into the earth—a science called stratigraphy.

When we got to the baulk trimming lesson, the square supervisor said, “OK, everyone grab your Marshalltowns.”

I had no idea what he was talking about. I looked around and watched as nearly every person in my square pulled out a Marshalltown trowel—some shiny and sharp (clearly the educated first-timers), and others with trowels that were worn, some with re-taped handles, leather belt holsters, and always with their names or initials either engraved or Sharpied onto the steel—all still as sharp and straight as the day they bought them. These were the enlightened ones who had clearly been assigned Kent Flannery's 1982 American Anthropologist article, "The Golden Marshalltown," to read in class.

I pulled out the trowel I bought at Ace.

The square supervisor looked square at my trowel and said, “What…is that?”

It was high school basketball all over again. I didn’t have Air Jordans, and now I didn’t have a Marshalltown trowel.

“It’s a trowel,” I responded sheepishly.

The square supervisor responded, “That will be broken in a week.”

He was wrong. It took three days.

And that was how I discovered Marshalltown trowels.

***

Marshalltown didn’t set out to become an archaeological tool supplier, despite achieving this prodigious accolade. The Marshalltown tool company began in 1890, when two brothers, Jesse and Lester Williams, established a small machine shop in Marshalltown, Iowa, repairing bicycles and automobiles. Because they were crafty with metal, they also began filling occasional tool orders for local builders on the side. A local plasterer once asked if the brothers could craft some specialized tools for him. The resulting tools so pleased the customer that word spread, prompting additional local builders to seek out tools from the Williams brothers’ machine shop.

Noticing that there was a high demand in particular for their masonry tools, the Williams brothers established an assortment of trowels and began to market them. This was the first of many business decisions rooted in current market demands, coupled with foresight and investment in future business trends, even if meant shifting away from their current business model—repairing bicycles—a business that had been doing just fine. The Williams brothers’ anticipation of future market demands, while maintaining the quality of their existing products, would become the foundation stone of their business strategy.

As word of their trowels spread, they soon began receiving orders from outside of Iowa. They quickly shifted into a manufacturing and mail order tool business, and soon discovered that they needed more space. Thus, in 1902, they built a two-story machine, blacksmith, and automobile shop, complete with a boiler, engine room, and office. As demand for their trowels continued to grow, they began focusing on the manufacture of their high-demand tools, and called that part of their business Marshalltown Trowel Works. As sales continued to increase, the Williams brothers joined forces with salesman Albert Higgin and officially incorporated “Marshalltown Trowel Company” in 1905.

In 1909, the Williams brothers agreed that a large promotional tour would help bolster sales. So, they loaded a truck full of trowels and began a cross-country trek, actively pursuing sales and creating a network of distributors—another key strategy in their business model. Due to the outstanding quality of their product, sales skyrocketed in both the U.S. and Canada. The brothers quickly reinvested their profits in new machinery and expanded facilities. Simultaneously, Marshalltown began to hire additional employees from the Marshalltown, Iowa community.

World Wars I and II introduced Marshalltown to the European market. In 1918, the company supplied the U.S. Army with 18,000 trowels to aid in the American war effort in Europe. When the wars ended and American troops returned home, the Marshalltown trowels stayed behind, and swiftly became coveted by European builders—despite their premium cost—due to their superior quality and longevity compared to the European brands. Builders saw Marshalltown trowels as a small investment—one that paid dividends in durability and superior performance by outlasting other “disposable” tools.

As European orders increased exponentially, the extraordinary demand transformed Marshalltown into an international corporation. By 1930, what began as a small Iowa tool company had become the largest exclusive manufacturer of masonry tools in the world. Since then, Marshalltown has continued to grow into an international tool manufacturer. As they diversified their product line and began to acquire other companies, they formed a subsidiary, “Marshalltown Tools,” in Fayetteville, Arkansas, where they constructed a new production facility in 1982, and eventually established their shipping and distribution center. As they were no longer just a trowel company, Marshalltown Trowel changed its name to “MARSHALLTOWN” in 2003, and the company continued to grow and post impressive sales numbers.

One of the keys to Marshalltown’s success is the same operating strategy that they employed at the very beginning of the company: responding to current market demands while balancing a slavish commitment to the highest possible quality with maintaining a vigilant anticipation of future business trends. All the while, they were willing to make changes to current operating procedures even when the present business results presently appear satisfactory. Marshalltown CEO Joe Carter puts it this way: “MARSHALLTOWN already had the highest quality tools manufactured, as well as an incredibly-strong brand name within our industries, but we believed that by constantly improving our manufacturing methods, including robotics and automation, and expanding our facilities, we would stay ahead of the competition, continue to be the brand of choice for our customers, and be able to meet the customers’ needs.”

Marshalltown Director of Marketing, Jon Vance, says that this willingness to invest in improvements, including automation, warehouse expansion, and shipping, is what not only allowed Marshalltown to keep up with larger competitors, including foreign companies from Asia, but it also unintentionally aided in their survival, and even their flourishing, during the COVID-19 pandemic. As countries around the world shut down and people were required to stay home for long periods of time, large portions of the population chose to make improvements to their homes, including do-it-yourself projects and those requiring the hiring of contractors. One of the few industries to witness an overall boom during the pandemic was construction, as seemingly everyone wanted in on the home improvement trend. And because Marshalltown had already made the strategic decisions to automate and expand before the pandemic hit, they were in prime position to manufacture and deliver products when many other manufacturers and suppliers got caught in supply-chain slowdowns.

“This is another advantage of manufacturing and purchasing American-made products,” adds Vance. He points out that since Marshalltown trowels and the majority of their other tools are made in the U.S.A., Marshalltown was able to forge and ship products to their network of suppliers and retailers with little holdup. “Our CEO and Board’s strategic plan not only helped us weather the pandemic, it actually allowed us to thrive,” adds Vance.

I took a tour of the Marshalltown, Iowa factory, and was blown away by the sophistication of the technology, as well as their redundant safety measures, and the beautiful, massive new facilities that are used in the modern process of what is essentially forging (hammering) raw metal into various shapes. This, by the way, is the answer to why Marshalltown trowels are superior to others: they are forged in one piece. There are no welds to weaken and break. Likewise, while other trowels vary slightly from one another due to their overall manufacturing process that includes welds, “A MARSHALLTOWN trowel is a MARSHALLTOWN trowel, no matter where you buy it,” says Vance, as they are all forged in the same process, and manufactured here in Iowa. The process has changed with improved technology, but the workers on the factory floor overseeing these multi-million-dollar, super-precise, automated robots are still producing the same Marshalltown quality as ever before, only faster and in the safest possible environment.

Perhaps the most compelling aspect of Marshalltown as a company is the pride it takes investing in the local community. Joe Carter explains: “MARSHALLTOWN is one of many great manufacturers within the community of Marshalltown. Emerson (Fisher Controls) and Lennox Industries are two of the most famous. We are blessed to have a total workforce in the U.S. of over 600 people with nearly 200 in Marshalltown, Iowa. Our employees have helped us create a wonderful working environment that is safe, clean, and up-to-date.”

Marshalltown today is an international corporation, but we should not forget, that it was the simple trowel that made the company what it is, setting the standard as one of the most reliable brands in masonry. However, few people realize that Marshalltown also holds pride of place in the field of archaeology as well. It is not only the most trusted personal tool in archaeology, but it has come to symbolize excellence in the field. This means that Marshalltown trowels have been present for most of the significant archaeological discoveries made around the world.

I remember my second week digging in Israel—after being “gifted” a Marshalltown trowel following the demolition of my off-brand trowel (at the weld). I was picking near the baulk when following one particular throw of my pickaxe, I noticed something shiny. Realizing that I had just missed shattering whatever it was, I slowly began working the dirt from around the object’s edges with my Marshalltown, ultimately revealing an iridescent, heart shaped, Roman glass flask about the size of my fist. This had been buried for nearly 2,000 years, and my Marshalltown trowel helped bring it to light. It now sits in the Israel Museum’s ancient glass collection within the Samuel and Saidye Bronfman Archaeology Wing. And that discovery in my first season affected (some would say infected) me to such an extent that I’ve been doing archaeology ever since.

Eric Cline, Professor of Classics, Anthropology, and History at George Washington University and Director of the Excavation at Tel Kabri in Israel, has also used Marshalltowns throughout his archaeological career. In 1980—in his very first archaeological season—Dr. Cline discovered a small bronze Hellenistic piece in the shape of the Greek god Pan using a Marshalltown trowel while digging at Tel Anafa, Israel, staunchly establishing him as a career archaeologist from that day forward. That statue is also on display in the archaeology wing of the Israel Museum, following being on loan to the Hecht Museum in Haifa as part of an exhibit there.

Marshalltown has come a long way since it began as two brothers’ bicycle repair shop. The international manufacturing corporation is responsible for countless successful building projects around the world, all based on the success of the tools they forge right here in the U.S.A. But for all of the commercial success they have had, it is in the field of archaeology that Marshalltown is best known as the gold standard for tools—the Stradivarius, the Coca-Cola Classic, the Walt Disney Animation Studios, and the Nike Air Jordans—all rolled into one. The most significant archaeological discoveries in the Middle East are being made by trowels manufactured in the American Midwest, in a state-of-the-art factory in Marshalltown, Iowa.